-

CUSTOMER

Hauni Maschinenbau -

LOCATION

Hamburg, Germany -

INDUSTRY

Machinery for the Tobacco Industry -

PRODUCT

CorelDRAW Technical Suite

Since the spring of 2019, machine builder Hauni has relied on CorelDRAW Technical Suite with the XVL Studio 3D CAD Corel Edition Add-On for technical illustration and graphics. The challenge – easily process and make complex 3D data available for connected documentation systems.

Founded in 1946, the Hamburg machine builder Hauni has specialized in the production of complex special machinery for the cigarette and filter production. The story goes that the first sales call was conducted from a telephone booth at the Hamburg Dammtor... Today, the Hauni Group delivers its machines worldwide and employs approximately 4,500 people.

Although the company is meeting the changes in consumer behavior with suitable solutions, and production processes for e-cigarettes are increasingly in demand, the roots lie in the traditional tobacco processing. The “Hauni Ventis”, for example, is a machine for temporary storage to compensate for fluctuations in productions or to store cigarettes for drying. The machine receives its products conveyed in a bulk stream, and packages them in containers which are stored in a shelving system. Removal from storage takes place in the reverse order and via a ramp. The FIFO principle applies – the products first stored are the first to return to the so called bulk stream for further processing.

Hauni uses Siemens NX for the design of the Ventis and all other machines, thus creating complex 3D models of customized machines based on customer requirements. Once the actual production starts, they can prepare the data for the required documentation already at this early stage. Depending on the machine, 300 to 400 pages of operating instructions are not uncommon. Adding more languages, the content can quickly reach page numbers in the four-figure range. The objective here is to enable rapid understanding by using illustrations. Thus, they work with a lot of technical illustrations that are based on engineering data. At first, they export the data created with Siemens NX in the popular JT format from Teamcenter and then, in the next step, process it with XVL Studio 3D CAD Corel Edition.

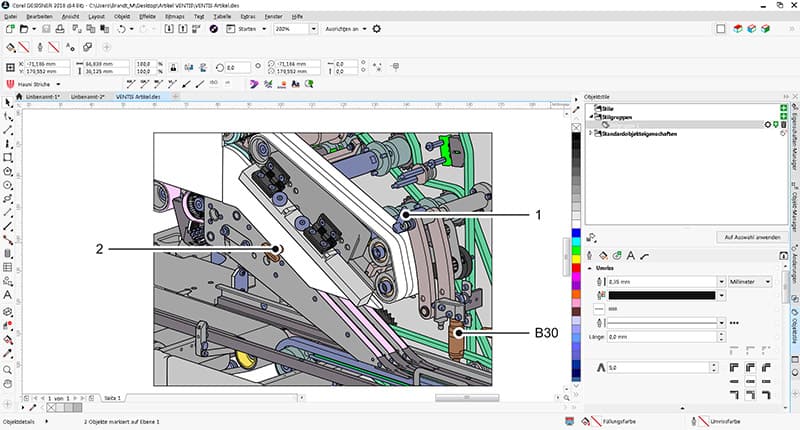

This software is, amongst other things, a specialist in creating exploded drawings, which play a major role in the technical documentation at Hauni. In XVL Studio, the technical illustrators can create and edit the view they want, showing or hiding components, adjusting the colors or generating cross-sections. Particularly the automated contour and surface creation (envelopes) proves to be a real time saver in practice. Based on selected parts, the software creates color-filled areas even if these don’t have a continuous contour.

Anna-Lena Schmidt, technical writer at Hauni, who participated from the beginning in the introduction of the Corel solutions, says: “Creating vector fills with XVL Studio saves a great deal of time when visualizing and highlighting individual components. What used to be done mostly by hand, can now be done in a few clicks.”

Once the data is finalized and arranged in an isometric view in XVL Studio, it is sent directly to Corel DESIGNER, another component of CorelDRAW Technical Suite, via an integrated interface. This application offers various special tools and features to process and enhance the data graphically. During the transfer of the data, the software automatically creates the thick-thin lining used in technical illustration. Then, callouts are created with the Callout tool, which adds an item number with a corresponding arrow to the relevant part. A preconfigured style template, similar to a paragraph format, is used to create the look and other settings of the callouts.

Warning symbols or other graphic elements such as hands, arrows or lubricant tubes not included in the engineering data can be added directly. As is usual with technical documentation, it is possible to prepare the drawings based on guidelines and specifications. This also applies, for example, to product liability. In this step, by switching in any parallel perspective, the user is able to directly draw and add elements in perspective, completely without needing CAD design software.

“Comprehensibility has top priority in the creation of our technical documentation. Therefore, we are adding important details to the engineering data that users will find useful,” says Michael Brandt, the person responsible for the introduction of CorelDRAW Technical Suite at Hauni.

If the engineering data changes during the product development process, these changes can be implemented into the illustrations that are based on the previous versions in Corel DESIGNER without loosing the edits that were already applied.

Even though Corel DESIGNER handles layouts of up to 999 pages, the technical writers at Hauni rely on an XML-based workflow in the editorial phase. In this process, they export the data in CGM format (Computer Graphics Metafile) and merge it with the text data to create the final documentation in their XML authoring tool. Basically, the German version of the documentation is always created first at Hauni, and will subsequently be localized to other languages. English will usually be first; however, depending on the customer, the documentation can be translated to any language.

Hauni required that the new software be compatible with the existing CGM format. For years, all drawings have been archived in this file format and the entire workflow is based on it. Because of the extensive archive and the proven workflow, changing the file format was out of the question. Since Corel DESIGNER supports importing and exporting the CGM format in all its versions and profiles, time-consuming conversions or workarounds can be avoided.

Smooth implementation

Prior to implementing CorelDRAW Technical Suite on almost 30 workstations, all employees underwent an extensive training provided by a certified Corel Partner. The Hauni team could not and did not intend to rely on chance or learning by doing. As early as in the decision phase, training partner Otto Salzer was available for technical assistance to ensure a smooth and uncomplicated start with CorelDRAW Technical Suite.

Christian Schmähl of Corel Germany explains: “There are several factors to consider when implementing a new software. First of all, the users have to accept it. This is all the more important if an obsolete system is replaced, since usability, efficiency and ultimately having fun at work should not be ignored. Therefore, our approach of getting the training partners on board as early as in the evaluation phase has proved successful. Later in the user training, they can start out exactly from where our solutions are able to most effectively prove their strength in helping the users with their tasks”.

Just a few weeks after implementation, the first technical documentations were created using CorelDRAW Technical Suite, including for the Hauni Ventis – in a smooth and reliable manner and with plenty of “drive”, much like the complex machines of the company.

Copyright for all images: Hauni GmbH