-

COMPANY

Porsche -

LOCATION

Germany -

INDUSTRY

Automobile -

PRODUCT

CorelDRAW Graphics Suite and Corel DESIGNER

After a re-engineering project, CorelDRAW delivers the goods as a powerful and cost-effective tool.

Porsche's claim to combine the doable with the seemingly impossible applies not only to its product line, but also to its development and related processes.

In the area of technical documentation, the goal was to transform construction designs from highly complex 3D systems (CATIA) into repurposable and comprehensible documents used for assembly instructions.

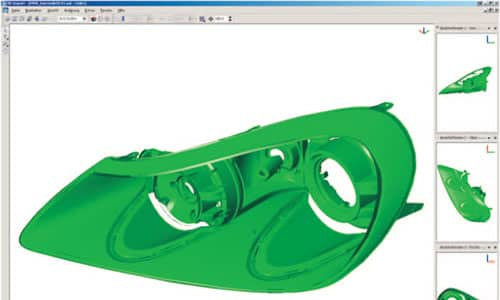

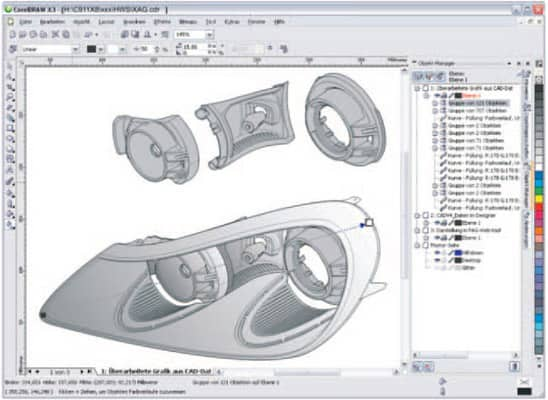

Porsche AG uses the CAD system CATIA (v.4 and 5) for 3D visualization in the development process. For technical documents, Porsche has been using the easy-to-use graphics software CorelDRAW since 1996. CorelDRAW allows the engineers to efficiently edit the illustrations for the documentation.

Assembly instructions are typically developed in a 3D construction model. The conversion into an illustration can be very time consuming, especially in the absence of a direct or technically mature interface between the two environments. To close the gap between 3D model and illustration, Porsche AG approached Corel, and, working in close collaboration, Corel developed a direct 3D modelling interface that provides a highquality drawing basis for illustrations without burdening the engineers with extra work.

After a re-engineering project, CorelDRAW now delivers the goods for Porsche as a powerful and cost-effective tool. Today, from creating graphics in the design studio and presentations in the marketing department to processing assembly instructions, all departments across the company work with CorelDRAW.

The engineer or technical writer imports a native CAD 3D model into Corel DESIGNER Professional. The CAD 3D model can then be edited easily with the 3D import module. The tool allows the user to rotate objects freely, to apply cuts and to export vector graphics. The use of Corel DESIGNER has resulted in significant savings in time and money. It has streamlined the entire process and allowed for eliminating intermediate steps to external service providers.